We offer a full range of mould design and fabrication services, including:

- Custom mould design optimized for medical-grade components

- Tooling development in-house or in collaboration with trusted partners

- Small-format molds with reduced CAPEX for low to medium volumes, ideal for pilot runs or clinical batches

- Large-format, multi-cavity molds for high-volume production, delivering cost-efficient unit pricing

- Full support for design for manufacturability (DFM) and material selection

Our plastic injection molding capabilities include:

- Production in ISO7 compliant cleanroom environment

- Processing of a wide range of medical-grade thermoplastics

- High precision moulding for complex geometries and tight tolerances

- Fast turnaround times and agile changeover for different series

Whether you need a flexible, low-cost solution for small batches or a high-performance mould for competitive per-unit pricing, we are your reliable partner. Our technical team works closely with you at every stage, ensuring quality, compliance, and performance in every component we produce.

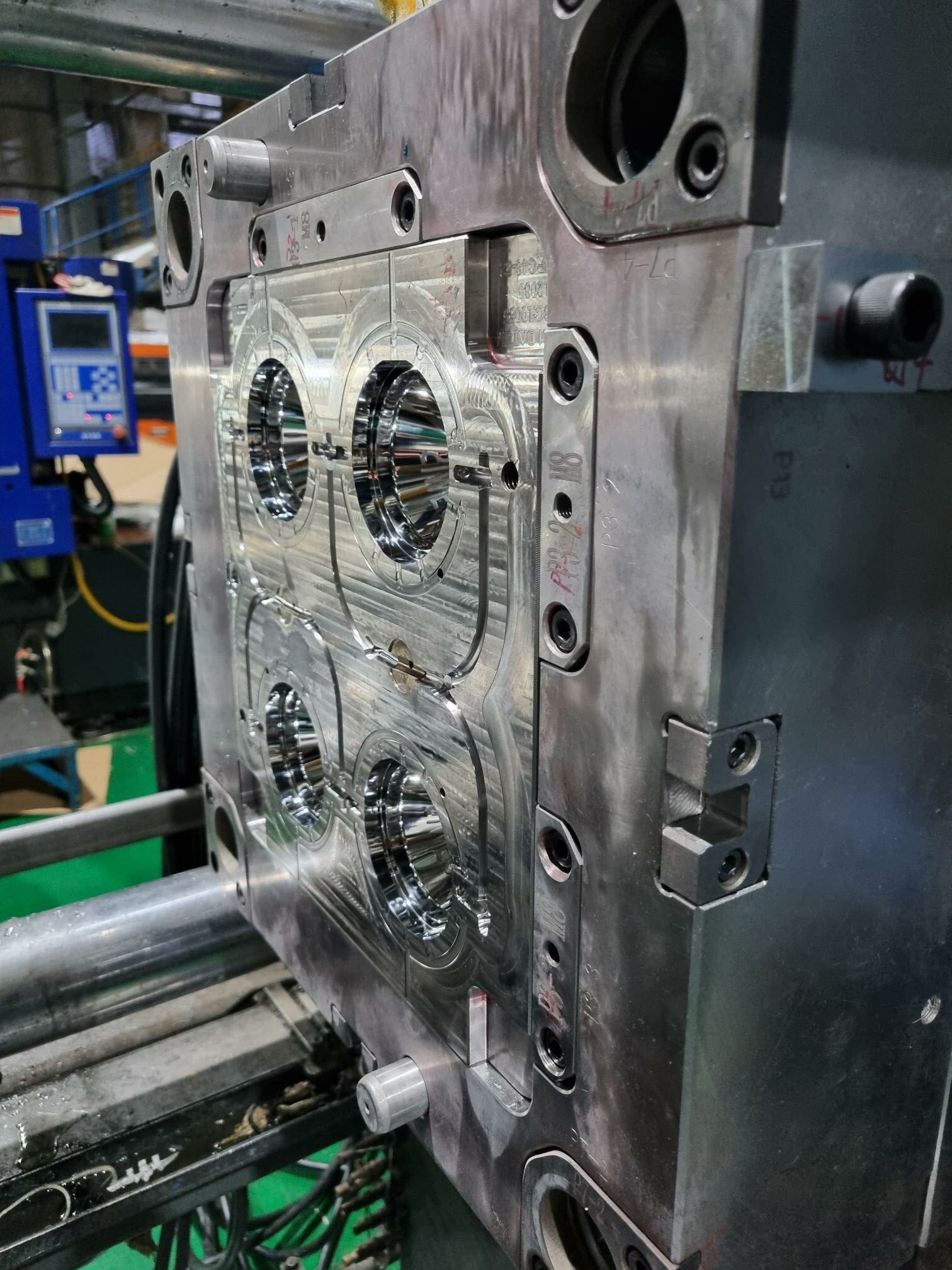

Injection moulding tool

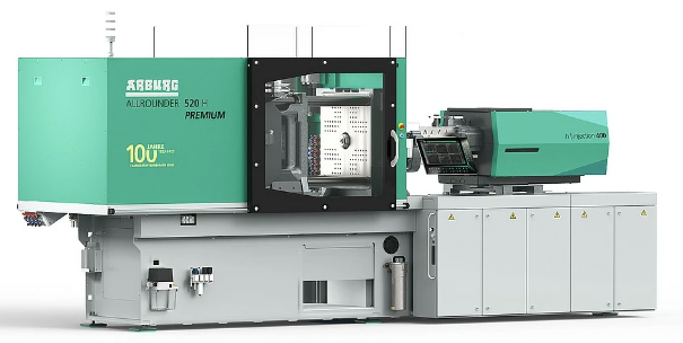

- Flexibility and expertise: Injection machines from 10 T to 320T

- Parts designing for injection moulding

- Moulds designing and management

- FAT / SAT / IQ / OQ / PQ

- Production lots from 100 pieces to 1 million pieces

- Overmolding capabilities

- Thermoplastics and Silicone parts

- Parts assembly